Fencer-1

-

Posts

198 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Events

Posts posted by Fencer-1

-

-

Similar, but not the same in shape and size.

- D.B. Andrus and BiggTim

-

2

2

-

-

-

-

As far as I know, this gauge is the same for all F-4.

- jeroen_R90S, alain11, LSP_K2 and 6 others

-

9

9

-

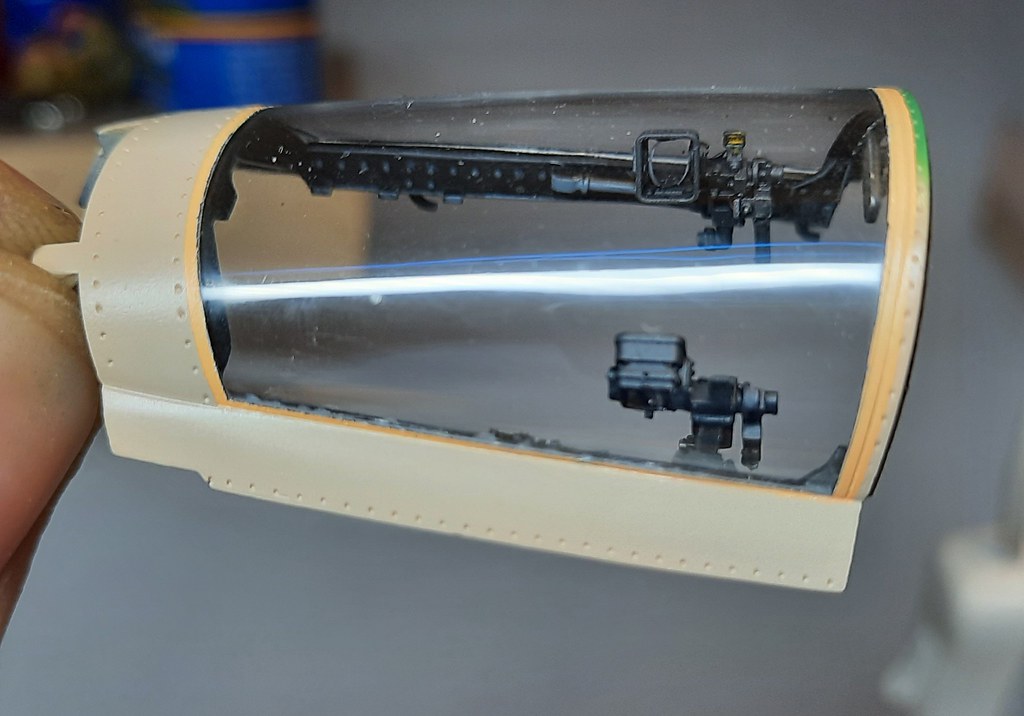

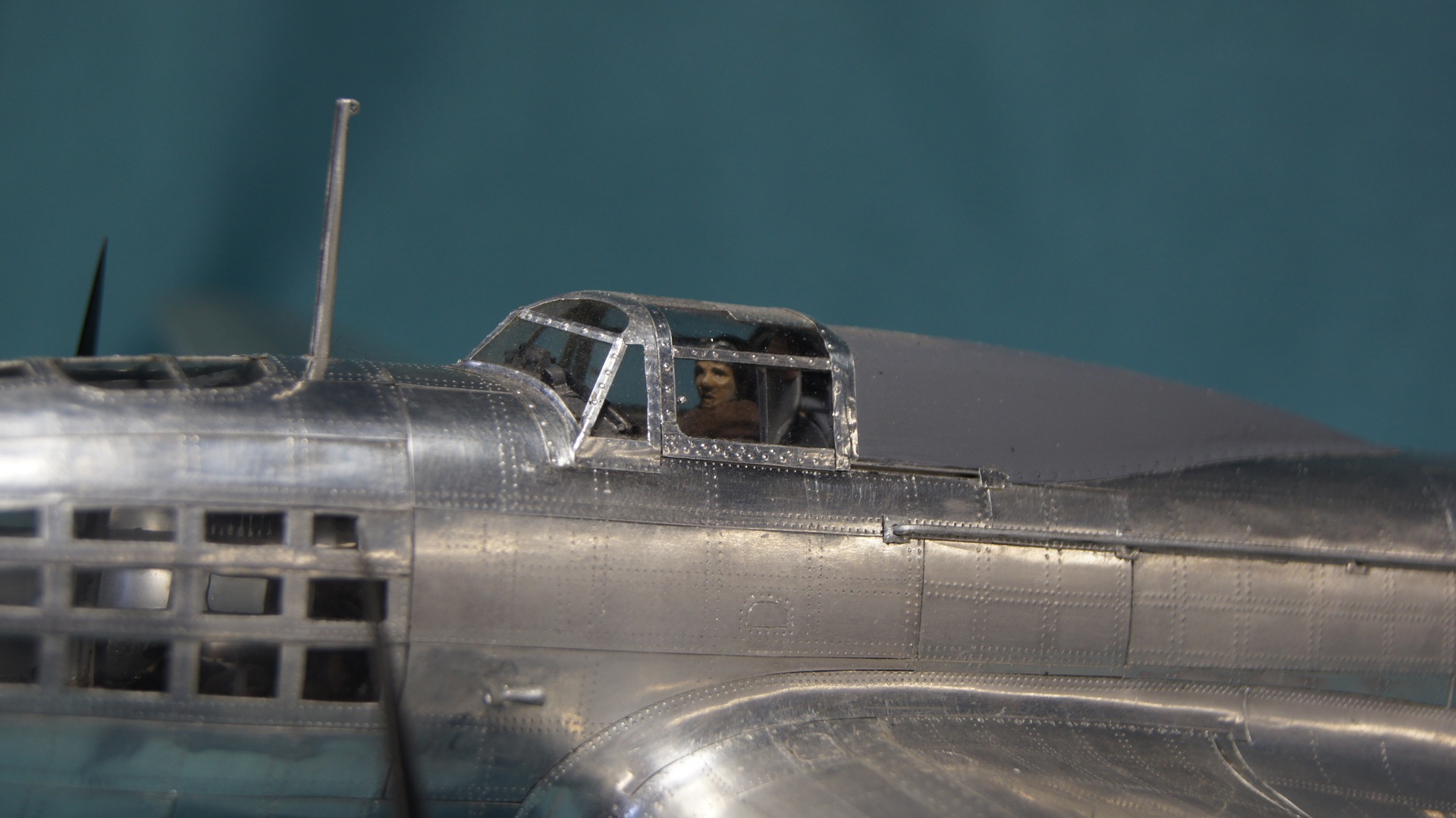

Rear canopy with LOROP camera sights. Sorry for phone qquality photo.

Front canopy details

-

On 9/20/2022 at 2:25 AM, alain11 said:

Okay , I didn't notice that at the first glance , thanks , maybe because I was focused to this excellent rendition

and by the opportunity of a Japanese RF4

and by the opportunity of a Japanese RF4

Alain

but is there a recce pod available somewhere ????

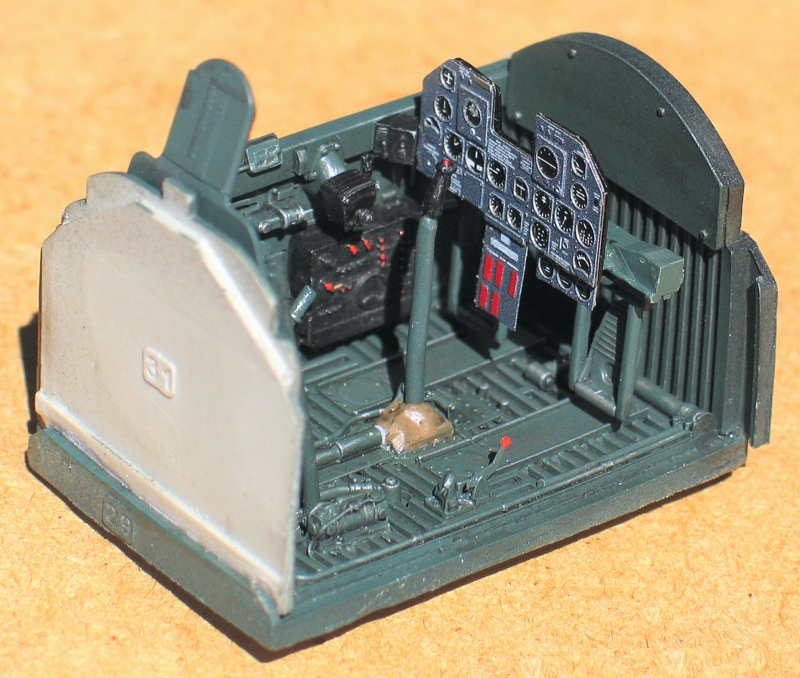

Thanks Thierry for explanation, yes, RF-4EJ is conventional Mitsubishi-built F-4EJ adapted to carry one of three (TAC, LOROP and TACER) reconnaissance pods. I intend to make one of them ( LOROP, I think) in 3D and then print. Many details are already made not only for cockpit, but for external airframe and engines.

- alain11 and thierry laurent

-

2

2

-

Just finished cockpit for RF-4EJ conversion from basic Tamiya F-4EJ. Quinta Studio + some custom 3D printed parts.

-

On 4/23/2021 at 1:09 PM, LSP_Ray said:

Is it possible some already in hand were used up? I assume they were interchangeable. There is typically a lag from drawings to implementation on the factory floor.

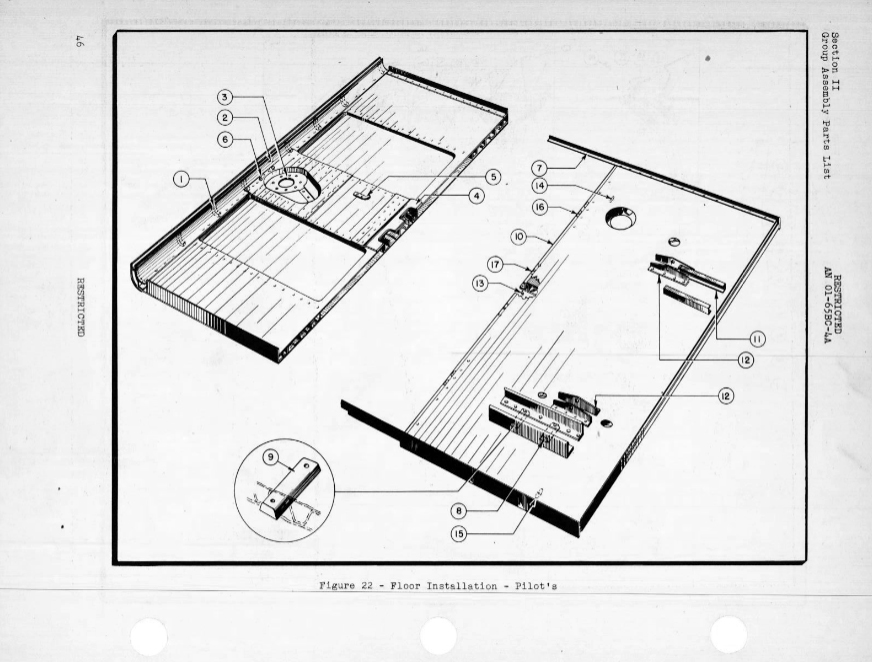

I had some thoughts about such possibility. Some sources hint at such hypothetical chance of using early floor parts up to D-30 series. I had to made additional research to make sure in my initial conclusion. There are two reliable sources I can refer to: "Parts Catalog for P-47D-25 Through P-47D-40" and assembly drawing 89F11237 for corrugated floor for all P-47 up to D-25 model. Catalog doesn't have any other reference than 93F12237 (flat floor assembly). Drawing 89F11237 has some remarkable note: "See drawing 93F12237 for later P-47 models. This assembly (89F11237) is not interchangeable with 93F12237."

- LSP_Ray and D.B. Andrus

-

2

2

-

4 hours ago, Vincent said:

No, it was not designed as an universal set, there can be no such thing on an a/c with so many versions and batches. If a razorback would have been released, I would have created the extra needed parts. Once again, at the time this set was created, there was some discussions going around that the very first bubbletops might have retained for a very short time the corrugated floors so I wanted to play it safe.

And no, I do not produce master patterns anymore, I leave this to the 3D printing folks

I absolutely understand the reasons for such option. It was unclear when the flat floor was introduced, but today we can prevent wrong choice making some notice with 100% reference from factory drawings.

-

7 hours ago, adameliclem said:

Hey Fencer,It’s ridiculously bad form to cite someone else’s work as an example of “incorrect choice.” Rather than single out another modeler for criticism, why not post images of your “correct” choices? I look forward to seeing them.

Adam

The only P-47D I've built is 1/48 old good Monogram as David Schilling personal mount. It was around 25 years ago, and yes, no exepition, it had incorrect corrugated floor also. I just didn't know the difference that time. Many models have just "universal" cockpit for all P-47 variants and Monogram P-47 is one of them. Why should we continue to repeat old mistakes again when we know how it has to be done?

- coogrfan, Harold and adameliclem

-

2

2

-

1

1

-

4 hours ago, Vincent said:

At the time I was doing the patterns, there was some dabate about the floor transition as well as the possibility that Hasegawa was planning a Razorback release. I created the corrugated floor for these reasons, "in case"

You are free to use the one you think was installed on the particular a/c you are modelling. Usually people complain about the lack of a particular part, not the extra options. By the way the set is designed with controls for both the Hamilton and Curtiss electric propeller so use the parts accordingly !

It's just wonderful to have an options and you make great work here, but there is no real option for Razorback Jugs because of lack of rear bulkhead, early seat mount, armor plate, radio etc. It is obviously not universal cockpit set and intended only for Hasegawa's Bubbletop P-47s. Am I right? Modelers continue doing mistake selecting corrugated (even making it from scratch like here Another Hasegawa Bubbletop) floor for Bubbletop P-47D versions. In case of your beautiful set totally unclear what second corrugated floor intended for. I'm just try to point attention to these details one more time.

With full respect to you,

Alex.

P.S. Fresh sample of incorrect choice: Beautiful Gabreski's Jug by Tolga Ulgur

-

By the way, all "Bubbletop" P-47D versions, including D-25 had flat cockpit floor. MDC cockpit mistakenly represents corrugated floor of earlier Razorback up to D-23 model.

Here is data table from Republic factory new flat floor drawing. It's clearly seen that it was installed from D-25 up to N-25 inclusive - all bubbletop series.

-

Very promising start! I like JASDF Phantoms.

My Hi-Res F-4EJ Kai & RF-4EJ walkaround from Hayakuri for the help: Hayakuri gate guards and More

My Hi-Res F-4EJ Kai & RF-4EJ walkaround from Hayakuri for the help: Hayakuri gate guards and More

F-4EJ Kai go around procedure at Hayakuri.

-

-

-

-

-

-

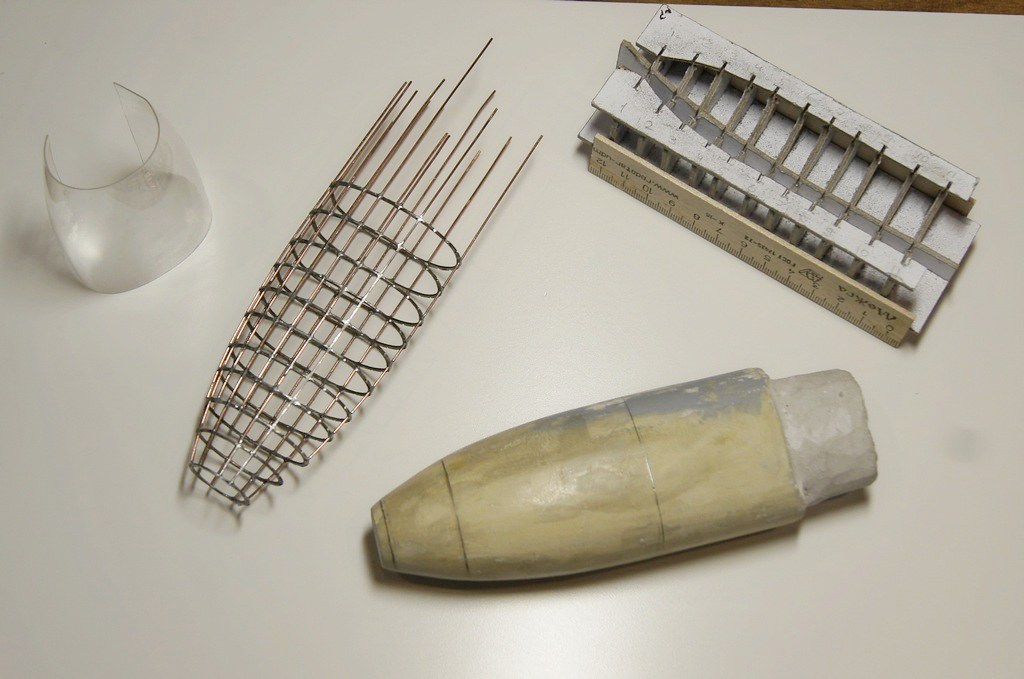

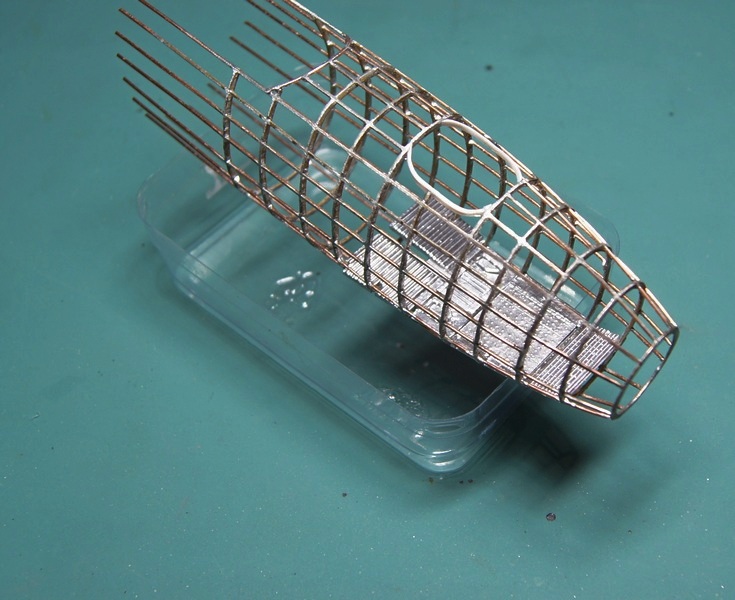

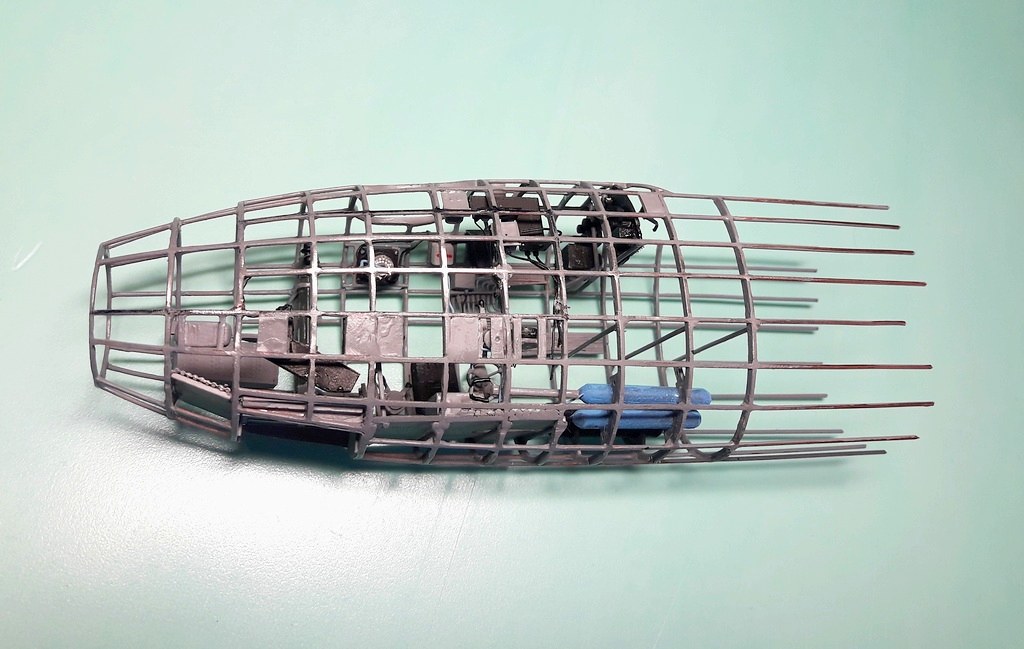

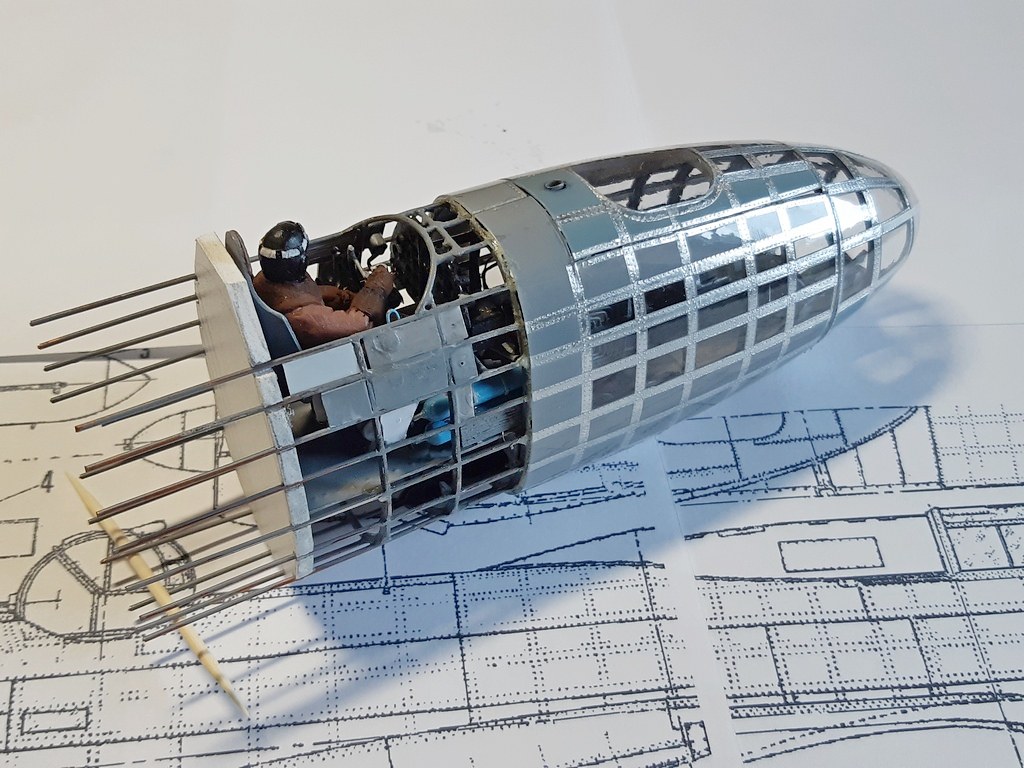

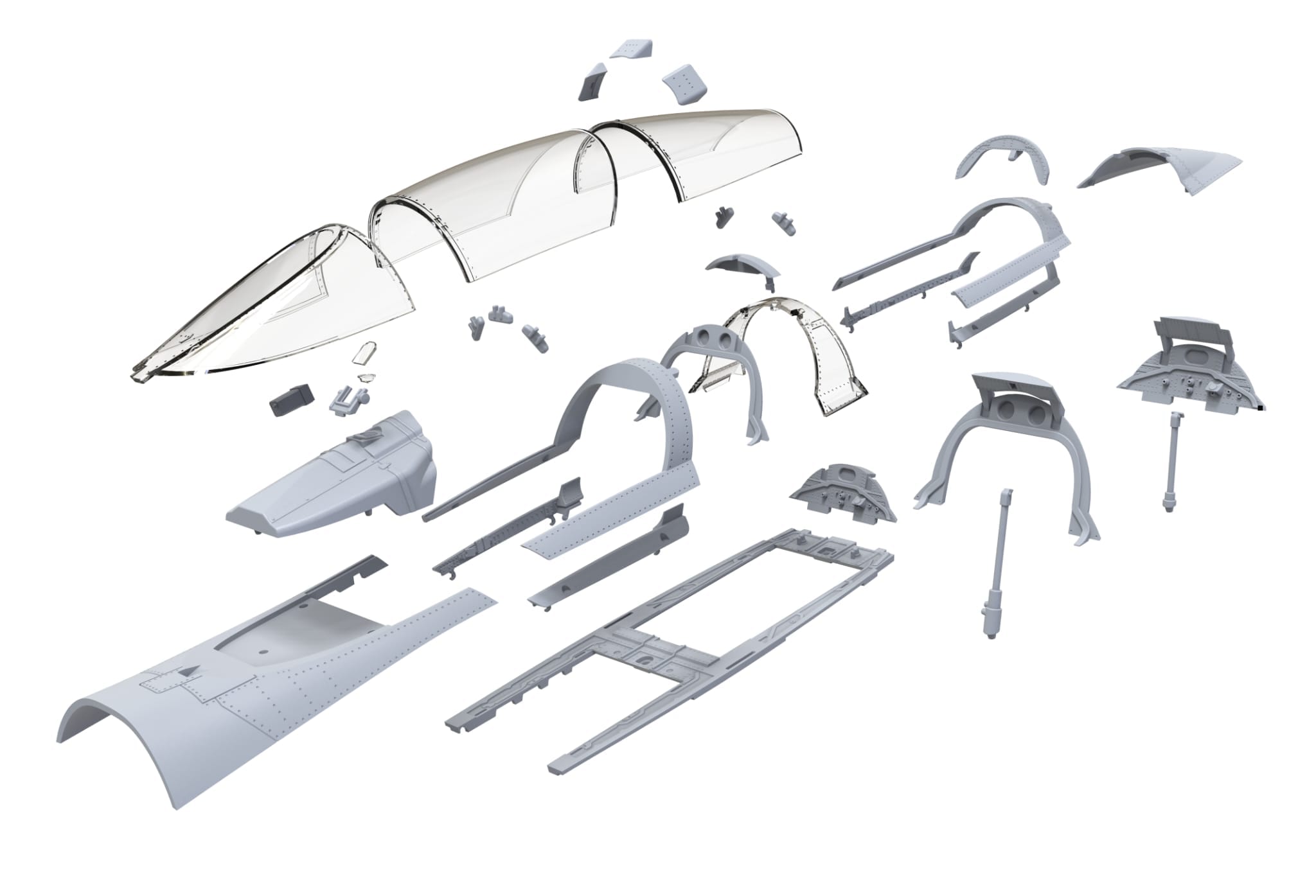

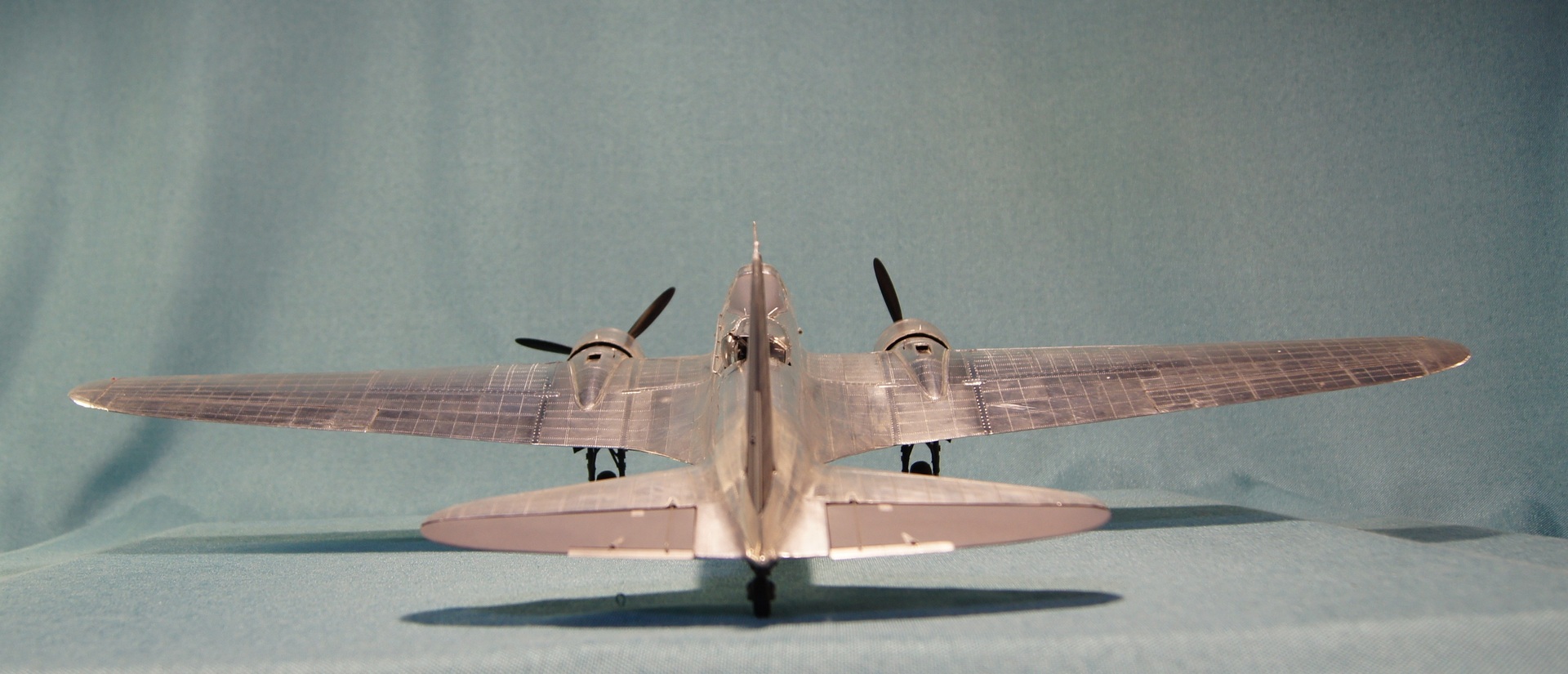

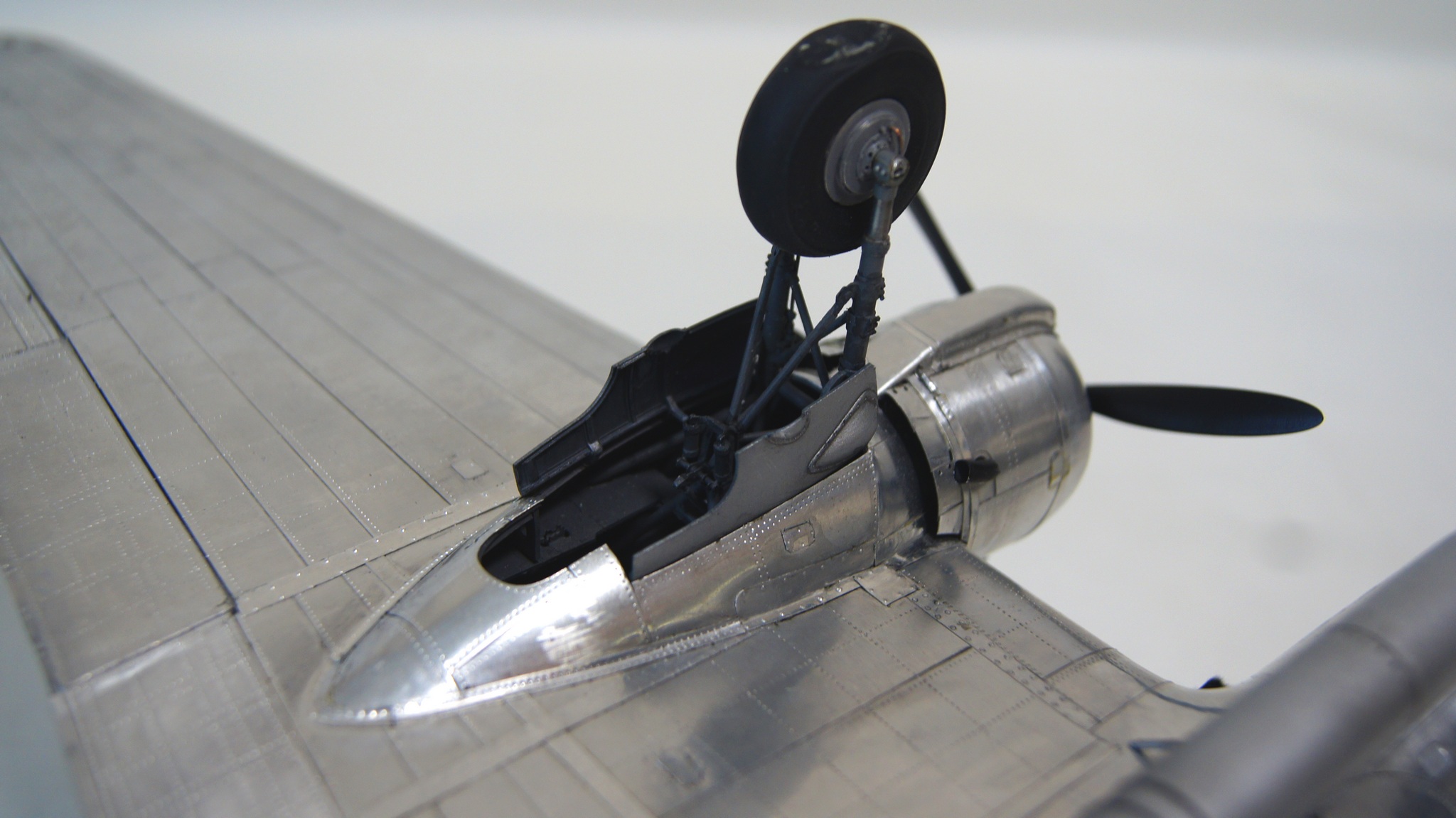

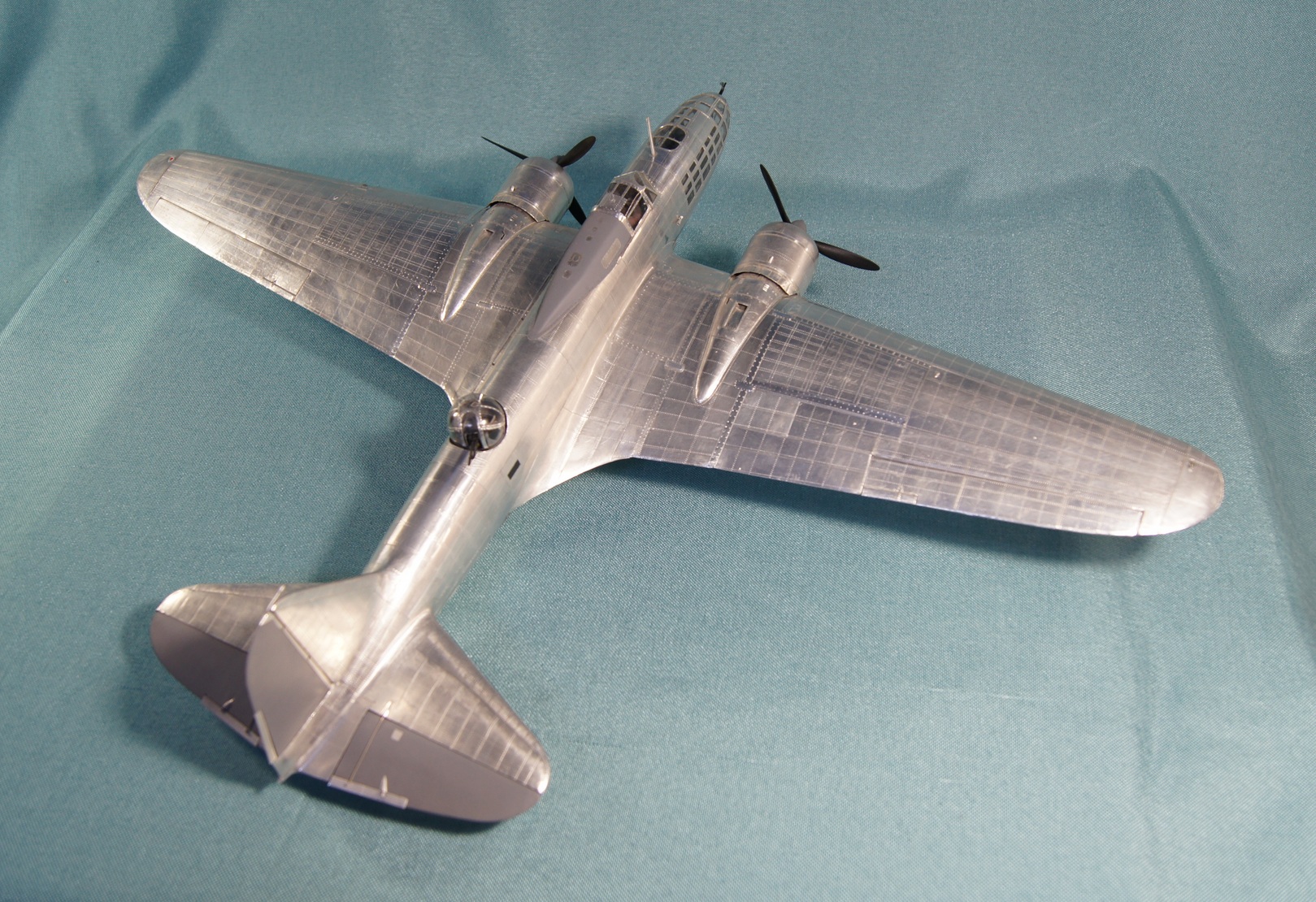

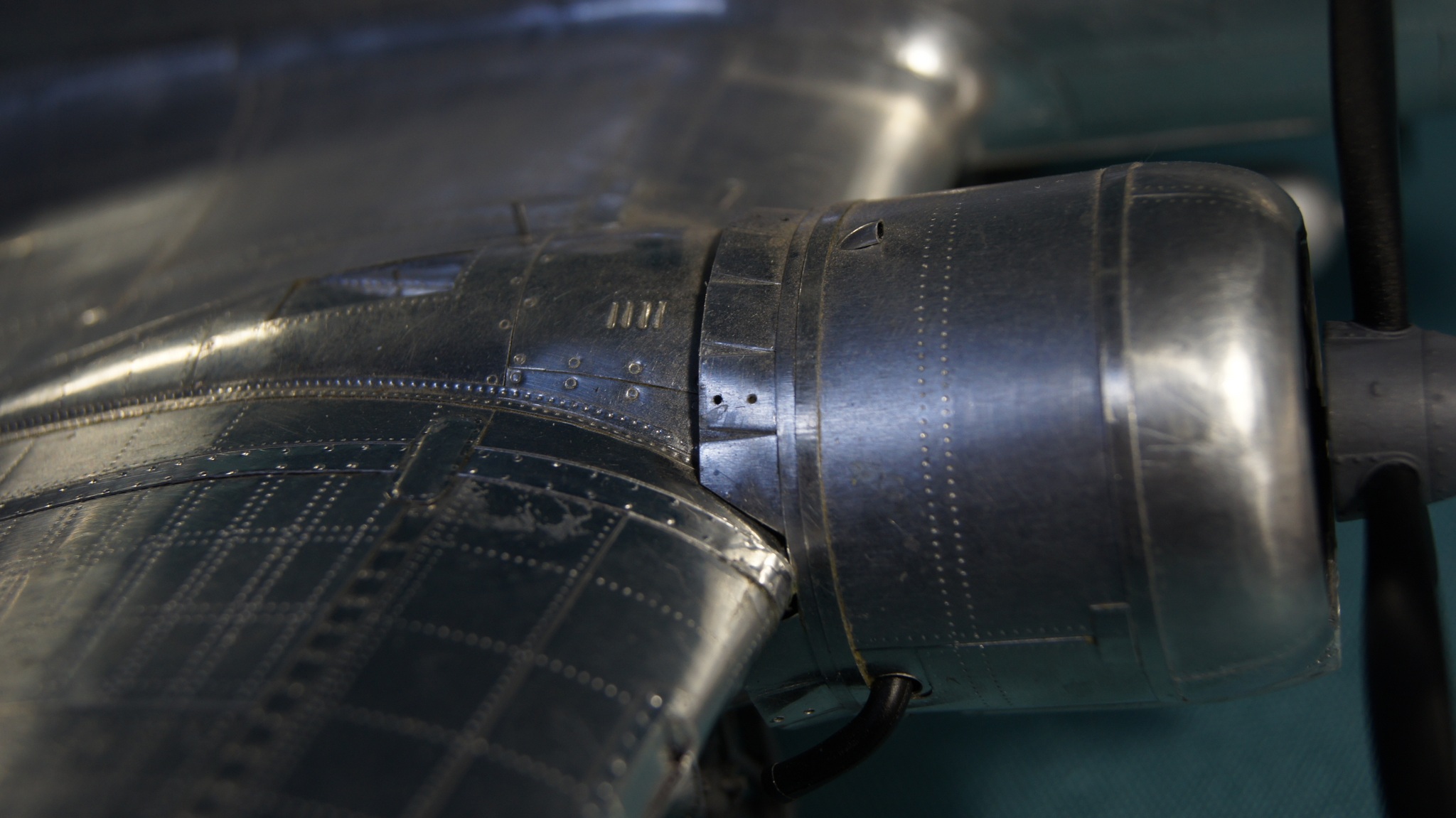

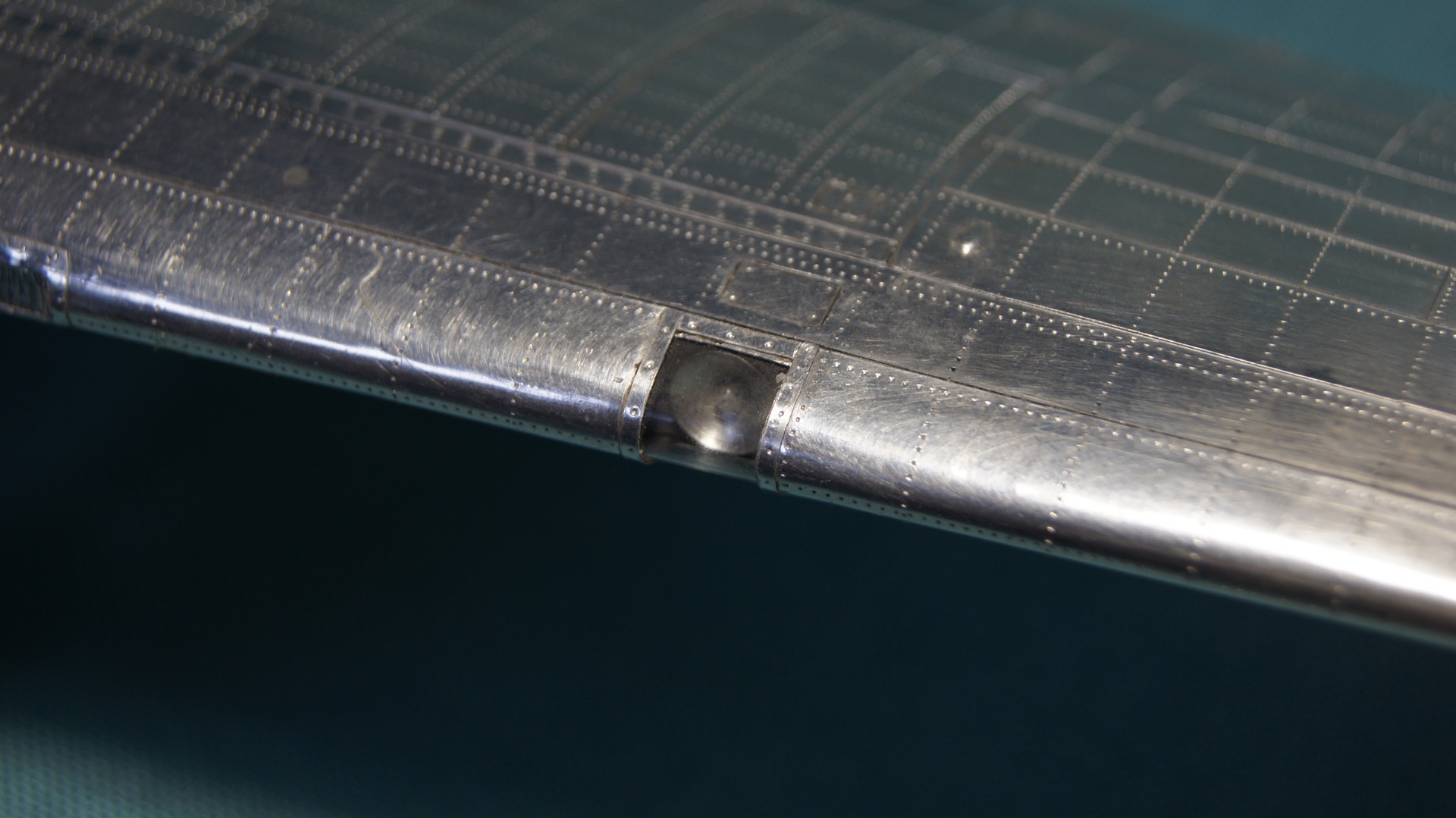

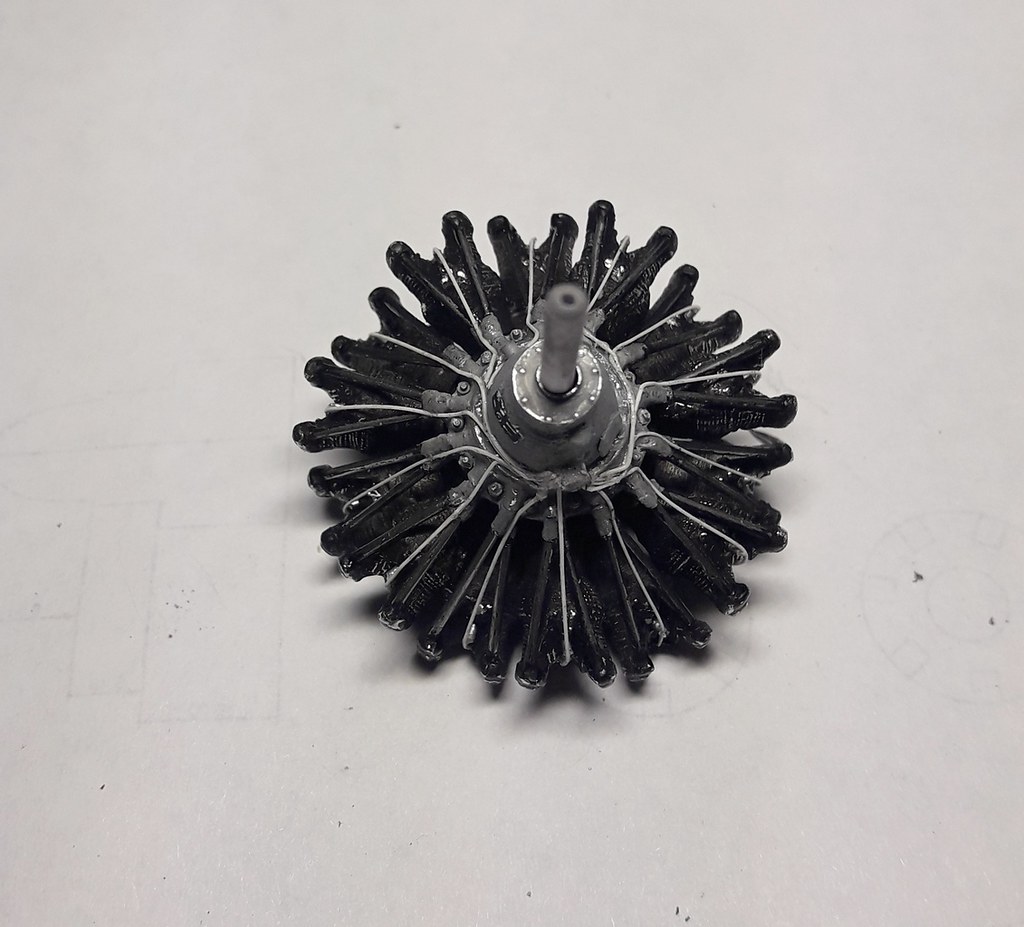

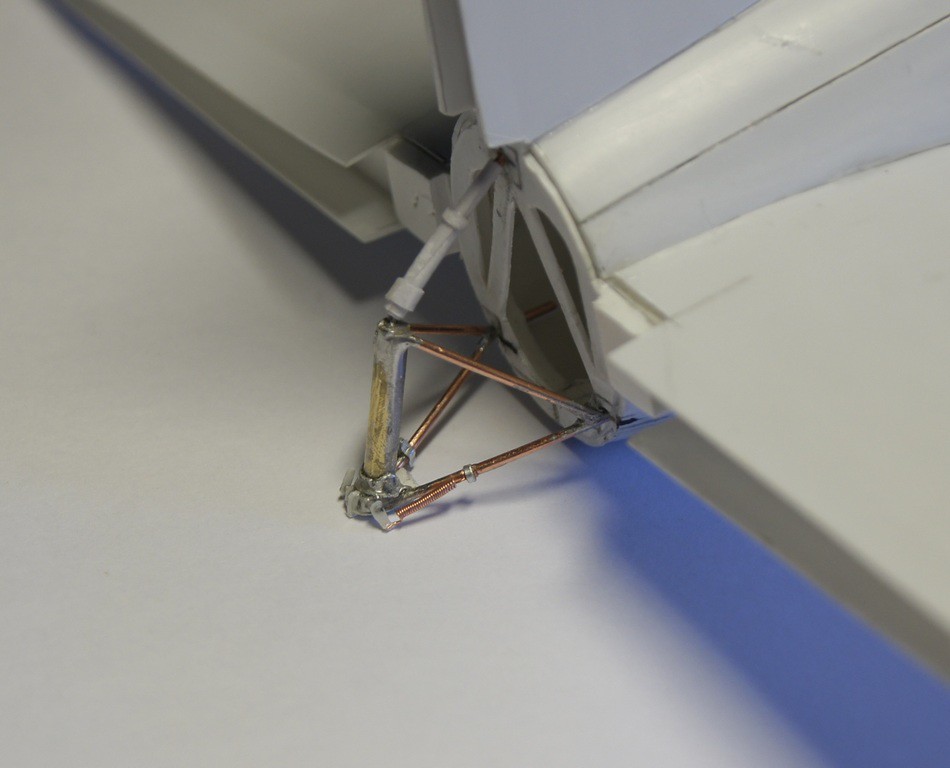

Please look at this brilliant work from Russian scratchbuilder Ivan Zhukov. I think that it is good idea to present it here with Author's permission.

The Author’s concise description and lot of photos below:

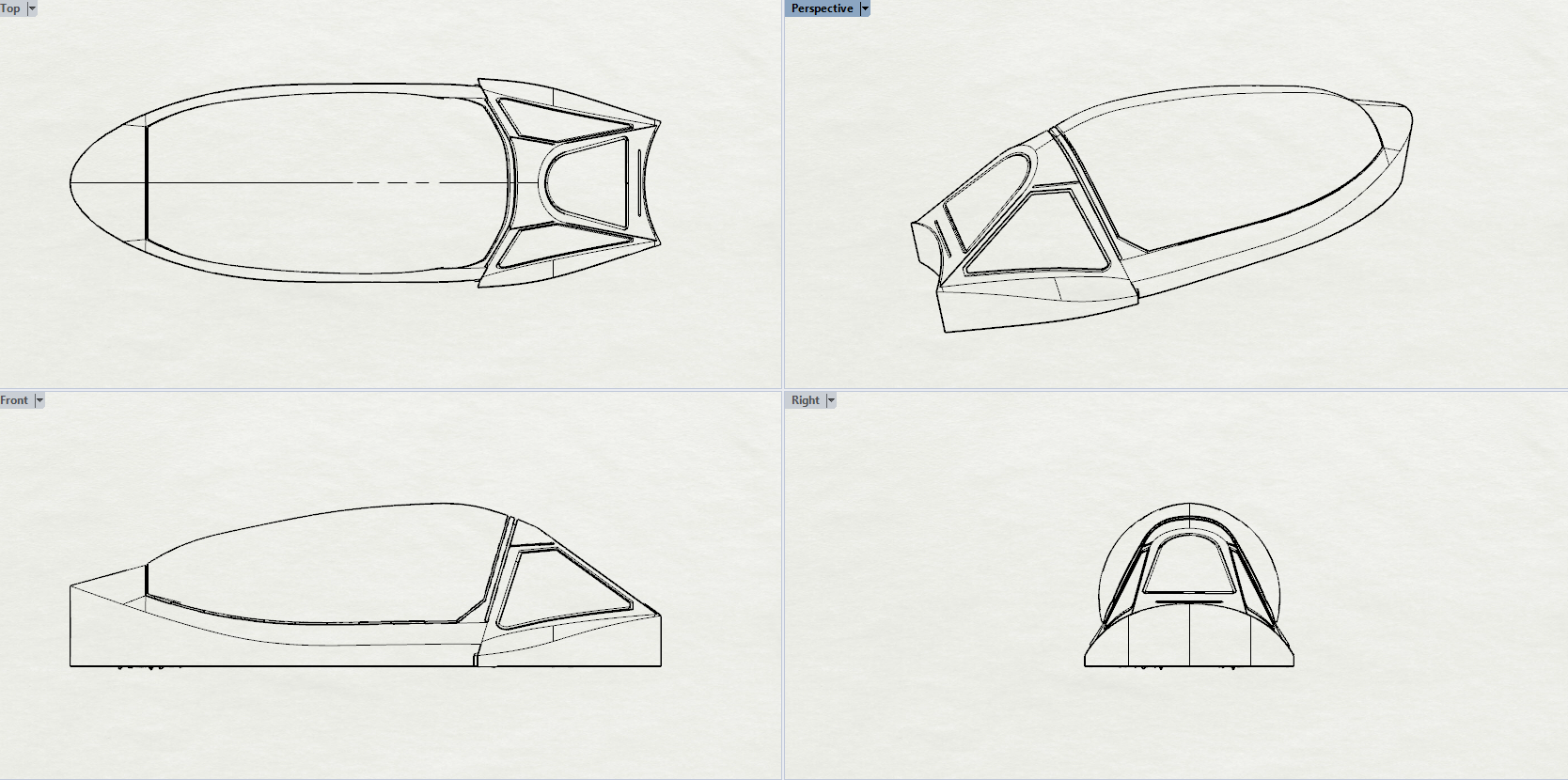

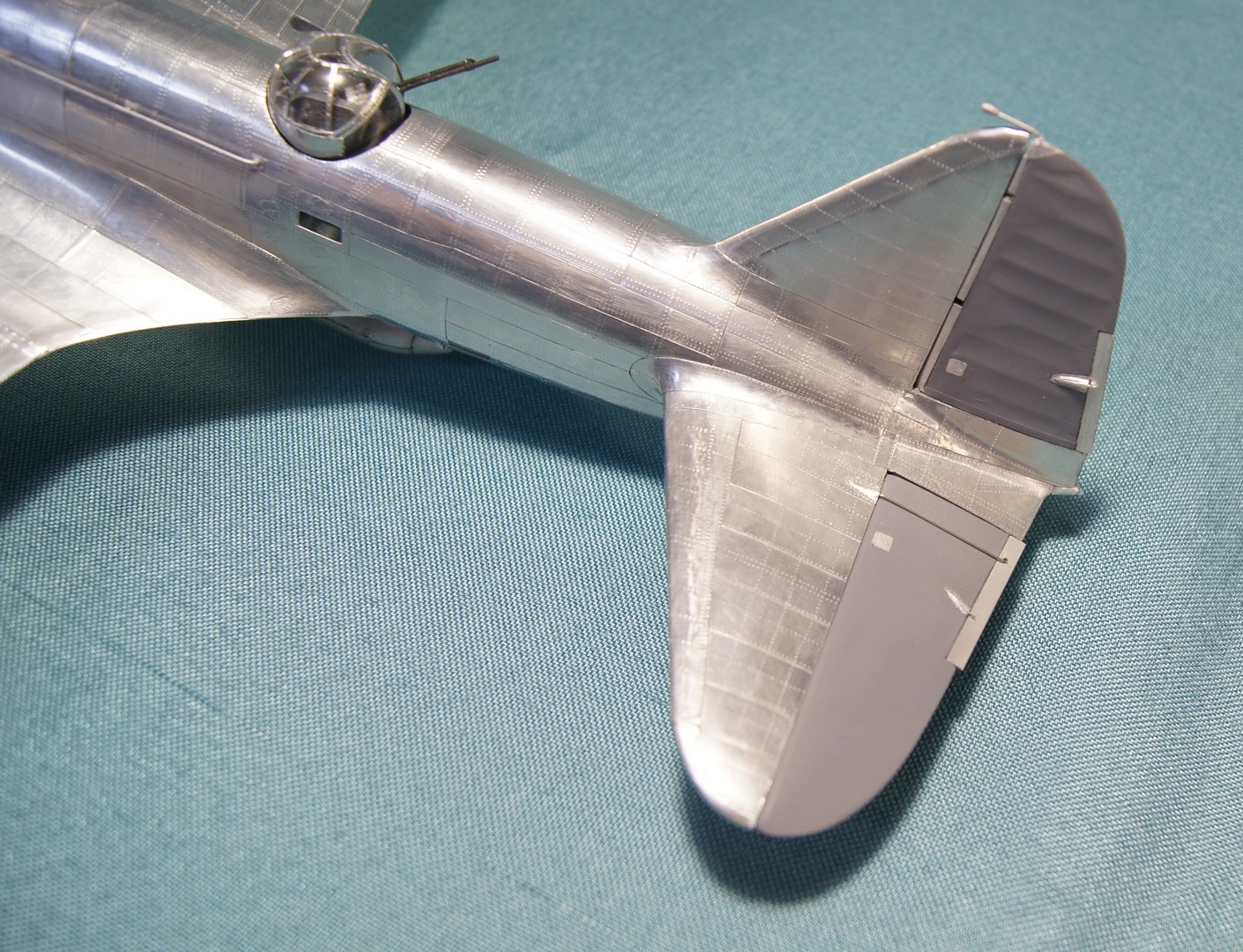

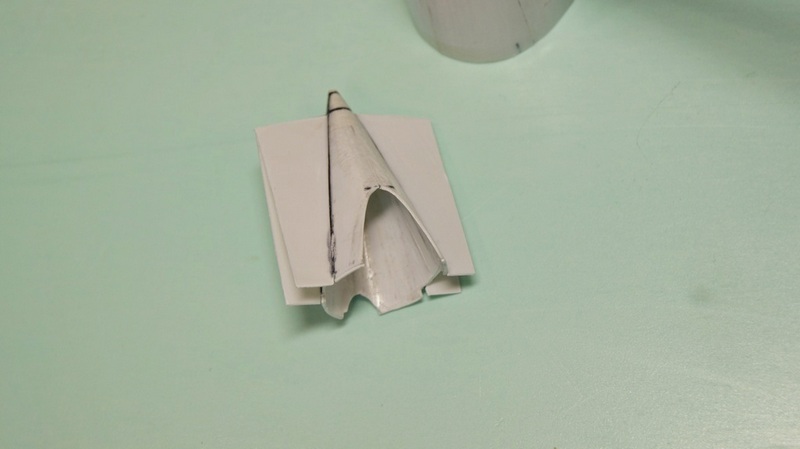

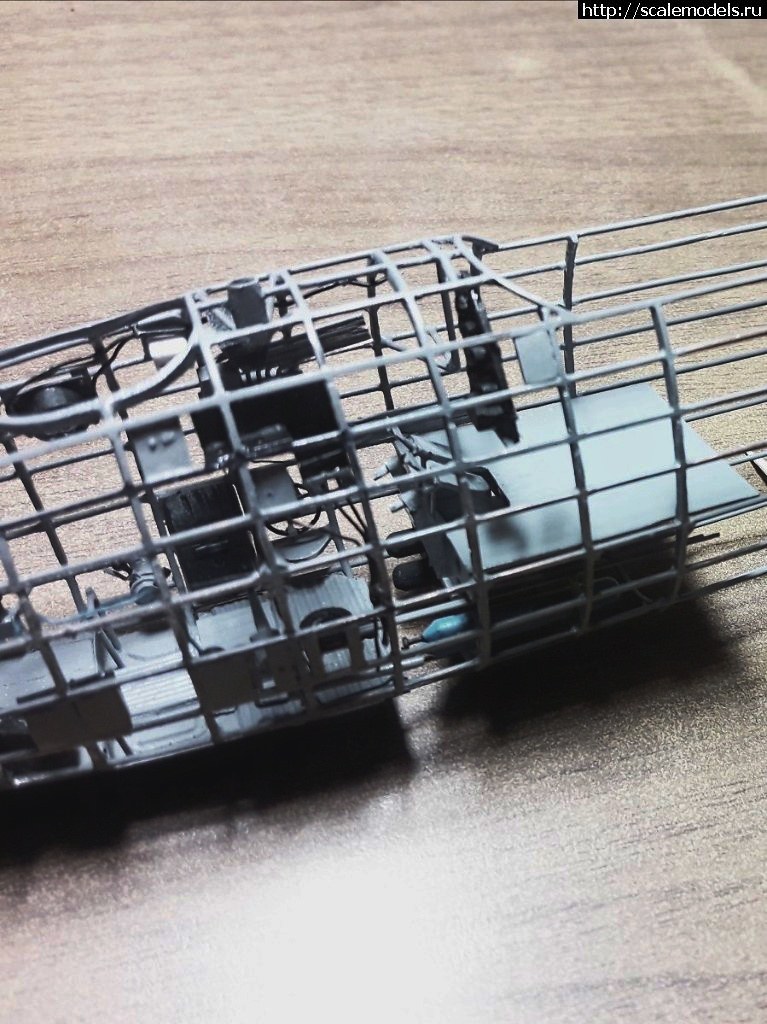

Initial work started 3 years ago with 3D model in Rhinoceros 4.0 to get proper shapes. Later 3D model was used as “master” to cut internal structure details. The main airframe components were cut from 2 mm foamed PVC sheet and covered by shell of the same plastic, but 0.7 – 0.9 mm thick. The nose section framework was soldered from 0.9 mm copper wire using cardboard jig and templates for frames proper shape and alignment, then nose section was stuffed by all necessary equipment and “avionics”. The crew was modified from various plastic figures parts using two component epoxy putty. Cockpit glazing was thermoformed over plaster moulds. The M-88 engines are totally scratch built, using white metal casting for cylinders. Wheel wells interior structure and landing gear are soldered using copper wires, brass tubing and sheets. The next tricky task was to cover entire airframe with aluminium skin. The same technique, as Peter Castle’s (Airscale) one. Forming, cutting, riveting and so on. Long, long way to finish. Tail control surfaces have plastic internal structure and 0.2 mm thick PVC skin. Wheels were formed in plaster moulds using epoxy putty. Some external addition such as torpedo and its racks, machine gun, gunsights, wheel well doors etc. were 3D printed and painted to finish the project. Wingspan of finished model is around 700 mm and length about 470 mm.

-

18 hours ago, Anthony in NZ said:

Wow, very nice!

I could see a tailpipe piece for the Trumpeter Skyhawk looking really good done like that!

Lovely

To be honest I and my friend have been thinking long time about F-100 rear fuselage skin.

-

18 hours ago, D.B. Andrus said:

Fencer, what adhesive would you recommend for steel to plastic?

Cheers,

Damian

Hello Damian.

The best choice is some kind of contact glue. Application technique is the same as Peter Castle (Airscale) uses for thick aluminium foil. In some cases I can use "slow" or Extra Time super glue gel. Before application parts usually being annealed and formed to conform to the surface. The thin (0.05 mm) steel surface is very strong and will not be affected by glue underneath. After application parts can be polished to get necessary tint and shine.

Regards, Alex.

-

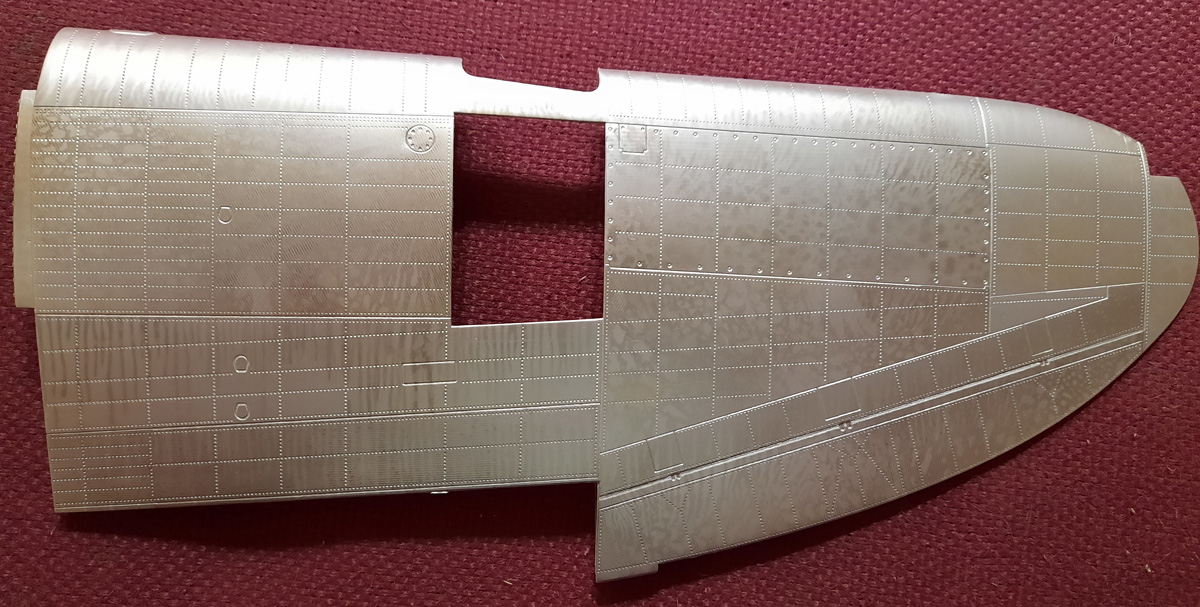

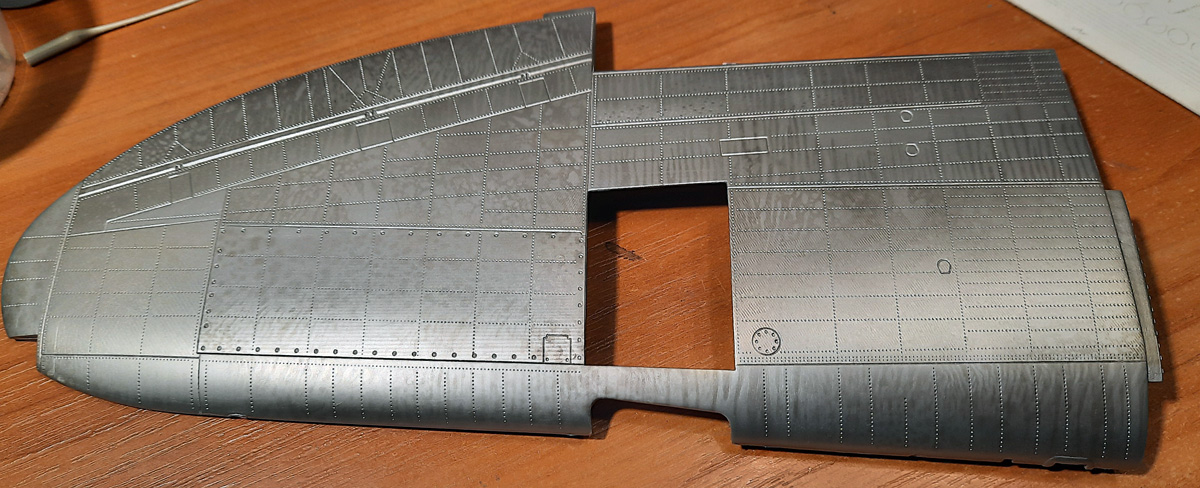

The parts made of steel, as on real thing. How do you assess them?

-

A.M.U.R. Reaver will offer new PE Set next week. There is set of four patterns for different effects, from fine regular grains to irregular stains and splashes. I "played" them yesterday using 1/24 P-47 wing for metallic paints effect test. They are very thin and flexible but very robust, because they are made of 0.05 mm stainless steel and will serve all the lifetime.

P-47C drain & vent tubes diagram (for those who like accuracy)

in Aviation Discussion & Research

Posted

Yes, but there are several differences inside D-series, so I will have to draw more))